Non Contact Coatings Thickness Measurements

Innovative in-line solution for measuring the thickness of coatings in harsh industrial environments.

Enovasense develops an innovative technology for the control of the thickness of all kinds of coatings (paint, polymers, organic, ceramic, metal, clearcoat, glue, etc) on all kinds of substrates. This laser device allows a quick punctual measurement, without any contact with the part to measure and non destructive.

So Where is the Technological Twist?

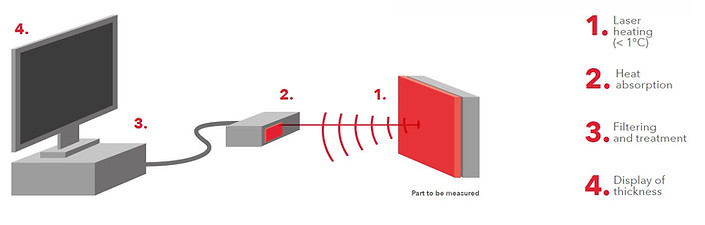

Contactless: The Enovasense device measures thickness without any contact with the part. Laser and infrared sensors are used to analyse the coating from a distance of 5 to 20 cm.This means that parts can be measured in their industrial coating environment, even when they are on moving lines, at high temperatures, still brittle or wet.

Non Destructive: Since very little heat is created by the laser beam, neither the coating nor the part are damaged or altered during measurement. As a result, each part can be systematically measured in industrial applications where, up until now, existing methods have required destruction of the test specimen.

Real Time: Measurement takes less than one second. Since the Enovasense process is based on a physical model wich allows to pre-calibrate the device according to the application concerned, calibration is both quicker and easier than it is for most existing methods. For some certain industrial applications, the Enovasense process can even eliminate the calibration step for certain industrial applications.

How does it work?

Main Applications